Capacity & Capabilities

Aalbers Tool & Mold Canada

Square Footage: 100,000

Employees: 150+

Crane Capacity (tonnes): 50

Press Capacity (tonnes): 3,500

Logistics (lbs): 80,000

High Speed Machining, 5 Axis: 135″ x 85″ x 47″ / 40,000 lbs

High Speed Machining, 3 Axis: 86″ x 68″ x 39″ / 22,000 lbs

EDM (tank size): X-59.4″ Y-101.2″ Z-31.1″ / 22,000 LBS

Plate Machining: 125″ x 75″ x 30″ / 8,000 lbs

Boring Mill Machining: 120″ x 78″ x 51″ / 26,400 lbs

Gun Drill: 130″ x 60.5″ x 46″ / 93″ Deep / 65,000 lbs

Lathe: X-9″ Y-20″ Z-40″

Aalbers Tool & Mold Mexico

Square Footage: 17,000

Employees: 11

Crane Capacity (tonnes): 20

Press Capacity (tonnes): 1,500

Logistics (lbs): 12,000

High Speed Machining, 3 Axis: 102″ x 35″ x 35″ / 4,400 lbs

EDM (tank size): X-80″ Y-40″ Z-24″

Plate Machining: 102″ x 35″ x 35″ / 9,200 lbs

Lathe: X-12″ Z-36″

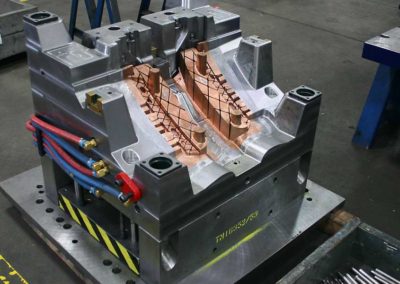

Mold Build

Aalbers Tool & Mold was started back in 1982 with the goal of building quality plastic injection tools. Over the course of the last 40 years we have remained dedicated and focused on that task. Using our experience and know-how, we guide first-time customers through the mold building process, and help develop unique solutions to the tool building process for experienced customers that need their challenges surmounted. From feasibility to final delivery, we look forward to getting quality injection tools made for you.

Repair Services & Support – Canada

With a dedicated team of 30 toolmakers split into 3 teams we are able to keep our repair services on track and out the door with a speed and efficiency that can surprise. With an average workforce experience of 10 years in the trade our support teams can quickly identify any issues and propose effective solutions for multiple tool sources. These teams have the full support of our production and high-end machining division to make sure that any tools that are brought to us are fixed right.

Repair Services & Support – Mexico

Aalbers Tool and Mold de Mexico is a full service mold repair company. Our 17,000 square foot facility is fully equipped with CNC and EDM facilities, as well as multiple hydraulic presses, an ALPHA laser welder, and a twenty ton crane. We offer home service assistance at your facilities.

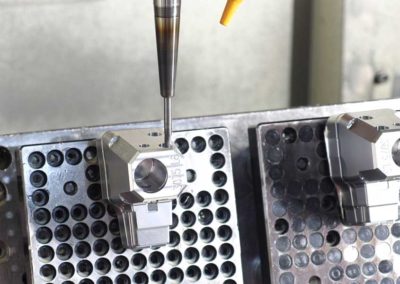

CNC Machining

Our state-of-the-art high speed CNC machining department uses the latest software and tooling for the most accurate surface finish attainable. Our high speed machining centres have 30,000 rpm spindles with feed rates in excess of 1,500 in/min. With the latest software and continued focus on improving our machining process, we will continue to be competitive in our ever-changing global market. At Aalbers, we strive to continue with the latest technology and utilize the highest quality machines from Kuraki, Makino, and Takumi.

3 Axis machining is the backbone of any machining plant, from boring mill work to large plate production, and our machines are up to the task. Our machinists line up each job to take advantage of each machine’s specialty, with a focus on speed and quality.

With brand new 5-Axis deep drilling machines our Gundrill department works closely with the mold designers to ensure that our cooling lines are able to approach the part from multiple angles easily and effectively without increasing setup time.

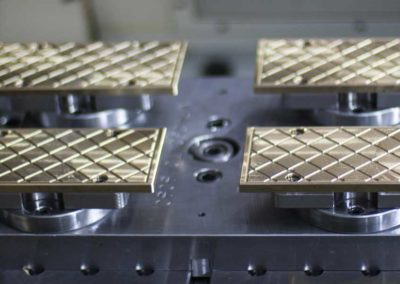

Components

Aalbers has a dedicated Components division that manufactures and stocks standardized components for our Molds. Having a fully tooled components division means aren’t subject to the risks of a supply chain. This investment ensures we maintain our 99% on time delivery rate. It also strengthens our service to our customers. If a customer needs a new part we have it in stock or can make it right away, This reduces downtime and gets our customers back up and running sooner.

Logistics

Our fleet of trucks, with a maximum load capacity of 52,000 lbs., operates 24 hours a day, 7 days a week, throughout Canada and the United States. Our professionals handle all the necessary customs and logistical documentation needed to deliver our products to and from your facilities.

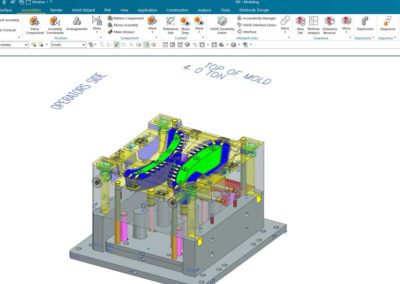

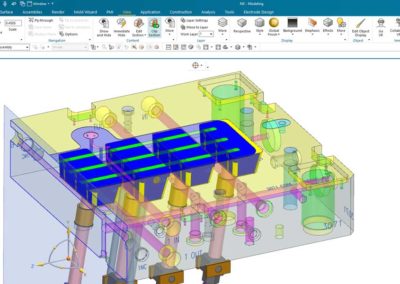

Mold Design

With an average of 25 years of experience across our designers and Program Managers we have setup a standardized component and assembly system utilizing the advance features of NX Mold Design – practically eliminating variance in tooling when molding similar parts. Our ongoing goal for the design department is to strive towards optimized tool designs for the highest quality parts and high efficiency manufacturing.

I was impressed with just how well the shop fit our description of a Lead Time Leader

— Matt Danford, Sr Editor Mold Making Technology