Automotive

Since our inception, our company has embedded quality practices in all areas of our business. Focusing on our automotive molding services we produce a variety of Injection, Compression, and 2 Shot Molds. Our team is experienced at supporting the production of high quality finished parts such as Interior Trim, Exterior Trim, Under Hood, and Console Assemblies. One of our specialties is producing Cloth Molded parts for interior Trim using superior techniques we have developed over the last decade.

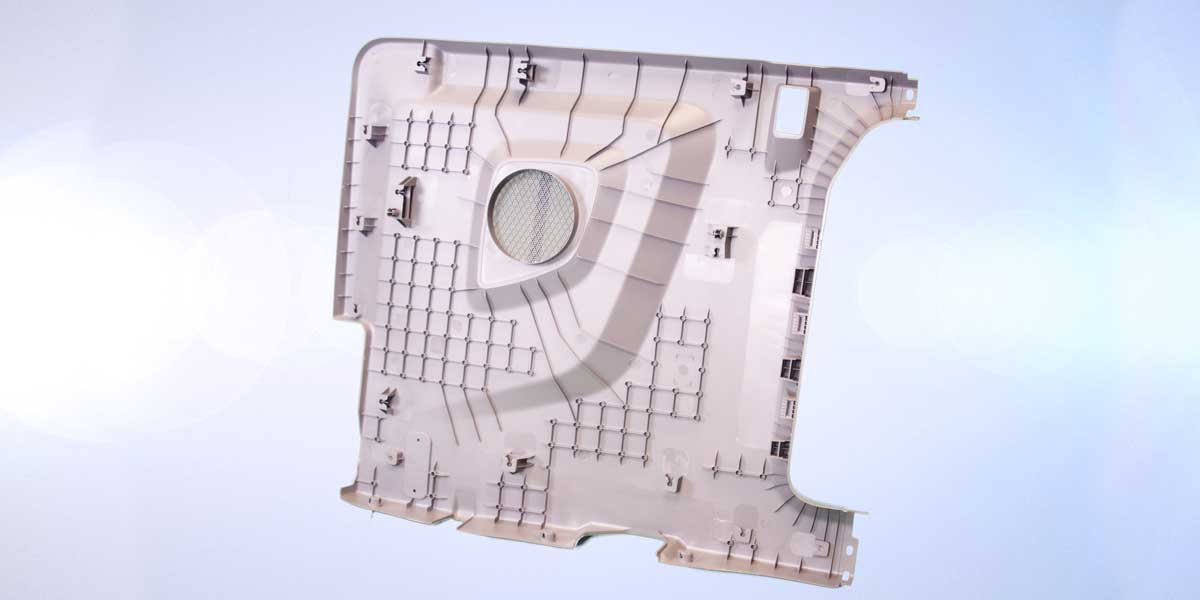

Interior Trim Parts

When it comes to interior trim parts there is a great variety of requirements that are unique to each type of part, from Zero Parting Line for grain matching to complex lifter and slide assemblies to form structural and mounting features.

Our team has plenty of experience in developing and making quality molds for A/B/C Pillars, Consoles, Door Inner Assemblies, Sliders, Liftgate assemblies, and many more interior parts with high visibility standards.

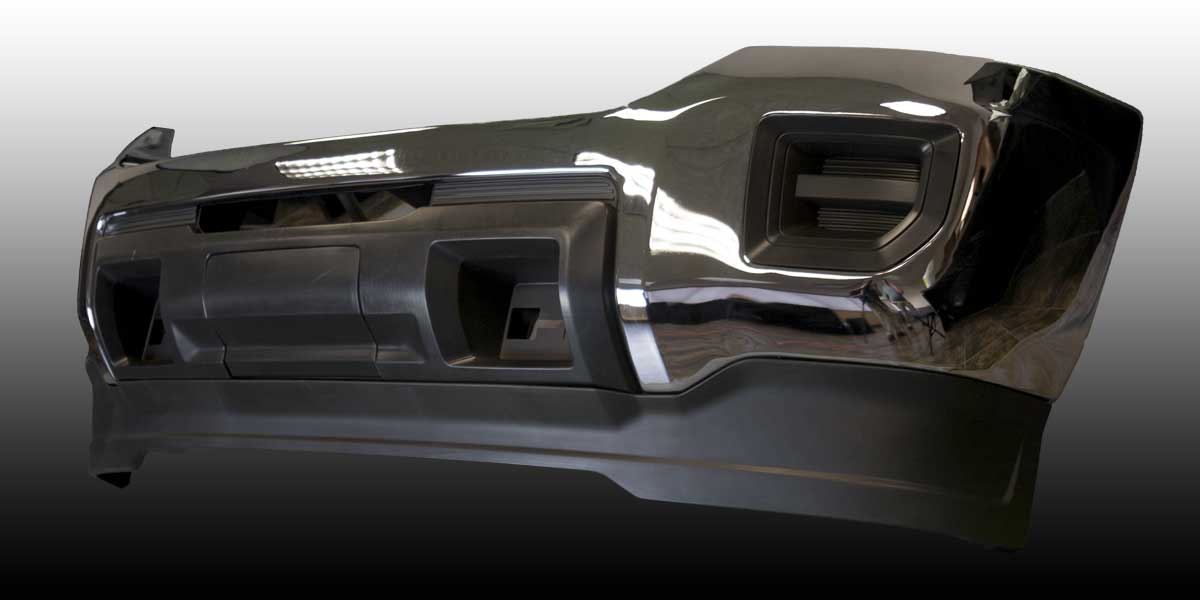

Exterior Trim Parts

Exterior parts face all the production challenges of complex and detailed parts but also often have a size limit that few shops are fitted to handle.

With the availability of a 50T crane and oversized machining we are capable of applying our expertise to the exterior parts. From Wheel Wells to Underbody plastic structure we work with our customers to make sure they are satisfied with all aspects of the tool.

Cloth Molding

Our cloth tooling group works with you at kickoff to review part data and type of fabric to determine the best location for stabber pins, evaluating likely pinch and wrinkle areas from experience with past programs, and consider adding additional actions if needed to ensure good parting line continuity.

When designing and installing the pins our designs often include spare pin locations for movement in the tryout facilities to adjust for wrinkles on the fly without having to cancel a tryout.

I was impressed with just how well the shop fit our description of a Lead Time Leader

— Matt Danford, Sr Editor Mold Making Technology